GENUS

SAP IMPLEMENTATION

User

Manual

PIR Creation/MRP Run/Convert Planned order to

Production order

PP Module

|

Version |

Comments |

Date |

Document No |

Revised By |

Reviewed By |

|

1.0 |

Final Release |

|

|

|

|

Review and Sign-off

|

Name |

Role |

Date |

Comments |

Signature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONTENTS

1. Business Process Details

1.1 Pre-requisites

for business process

1.2 SAP

General User Icons / Push Buttons /Table Reference

2. Procedural Steps

01. SAP Menu

Path & Transaction Code

02. Business Transaction Processing: PIR

Creation/MRP Run/Convert Planned order to Production order

Material Master

SAP component involved:

SAP Configuration like Plant Settings, Storage location, Sales org, division

Material types Valuation class, UOM, MRP Types , MRP ,Inspection types, Control

Key ,MRP controller Catalog types etc are the pre-requisites.

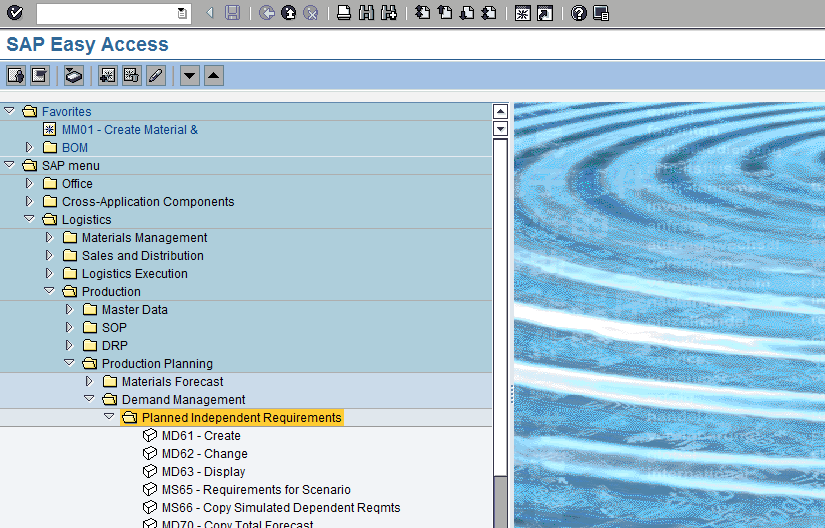

01.

SAP Menu Path

& Transaction Code: Create PIR

To carry out

the activity, Access transaction by:

|

Via Menus |

LogisticsàProduction à Production Planning à Demand ManagementàPlanned Independent RequirementsàCreate |

|

Via

Transaction Code |

MD61 |

Perform

the following steps of how to create PIR using the information below:

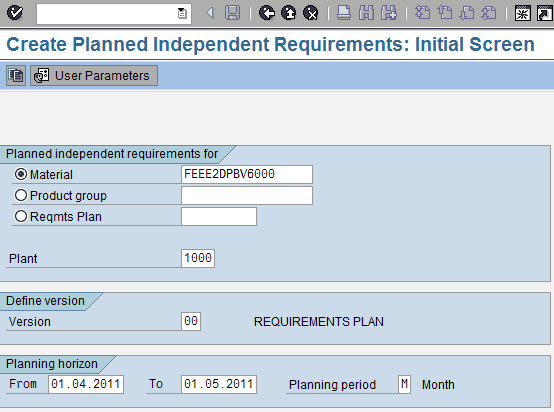

After click you will reach on below screen:

Fill the required data:

|

Field Name |

Description |

Values |

|

Material |

It should be Alphanumeric key uniquely

identifying the material. |

Example: FEEE20PBV6000 |

|

Plant |

Key uniquely

identifying a plant. |

Example:1000 |

|

From |

Start of the Period to Be Evaluated |

Example: 01.04.2011 |

|

To |

End of the Period of Examination |

Example: 01.05.2011 |

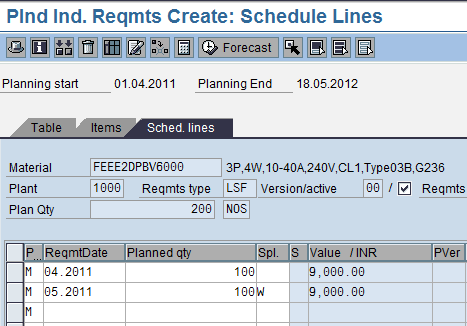

Now Enter: you will be on below

screen:

Now we plan to break May month

requirement in weeks.

Click on Schedule line tab

Click on Period indicator for

split

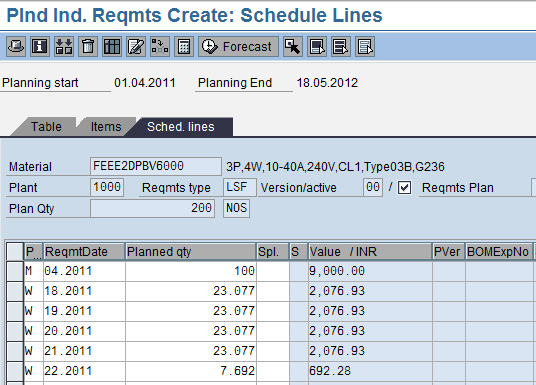

The screen looks like below:

System broke requirements into

weekly basis for MAY Month. You can round up the values.

Now do Save

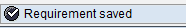

We can check these requirements

in Stock Requirement List/ MD04

Now we have to run MRP to cover

these requirements.

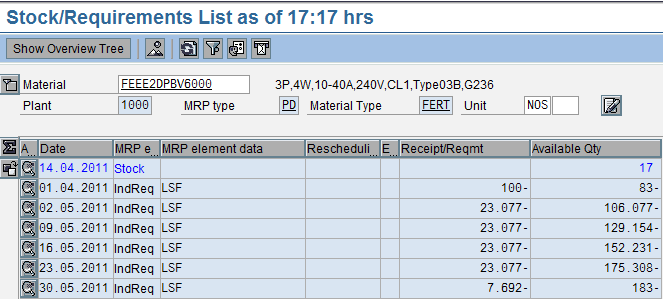

MRP Run

To carry out

the activity, Access transaction by:

|

Via Menus |

LogisticsàProduction à MRP à PlanningàMultilevel single-item Planning |

|

Via

Transaction Code |

MD02 |

Click on Enter Tab

|

Field Name |

Description |

Values |

|

Material |

It should be Alphanumeric key uniquely

identifying the material. |

Example: FEEE20PBV6000 |

|

Plant |

Key uniquely

identifying a plant. |

Example:1000 |

|

Processing key |

Specifies

the type of the MRP or MPS run |

Example: NETCH |

|

Create purchase

req. |

For

materials procured externally, this indicator controls whether purchase req or

Planned order should be created during MRP run. |

Example: 1 |

|

Delivery

schedules |

Indicator

controls Schedule line generation during MRP run. |

Example: 3 |

|

Create MRP list |

Indicator

controls MRP list generation during MRP run. |

Example: 1 |

|

Planning mode |

Defines

how procurement proposals from the last planning run are to be dealt with |

Example: 1/2/3 |

|

Scheduling |

Determines

whether only the basic dates are determined for planned orders, or whether

lead time scheduling is carried out as well. The indicator refers to all

planned orders that are new or have been changed or have been re-exploded for

the BOM |

Example:2 |

|

Also plan

unchanged components Display

results before they are saved Display material

list |

Make all

ticked |

|

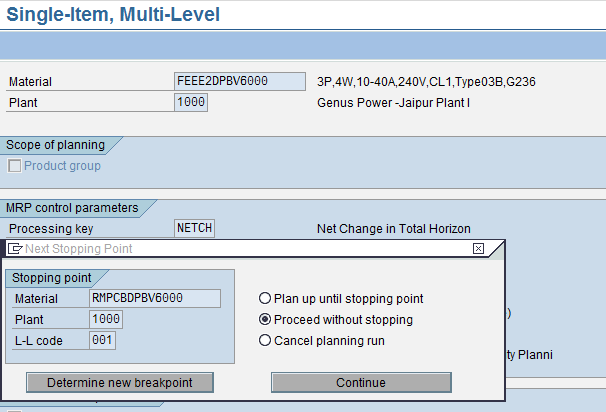

Enter, System will pop-up the

below message:

Do Save

Select

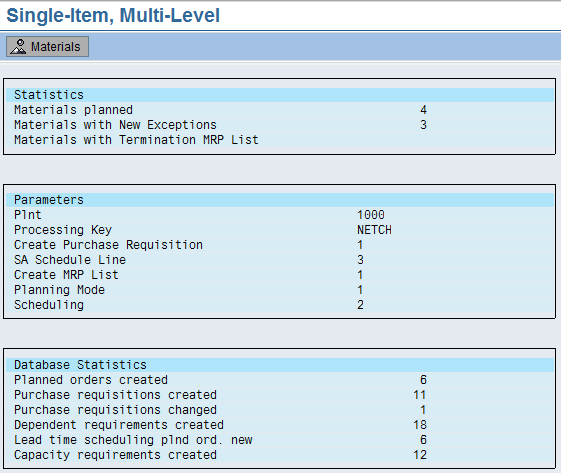

System will give the below

screen:

NOTE: This is all about the MRP run.

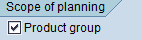

If

we want to run MRP for a PRODUCT GROUP,

Just select

Rest

of the process will be same.

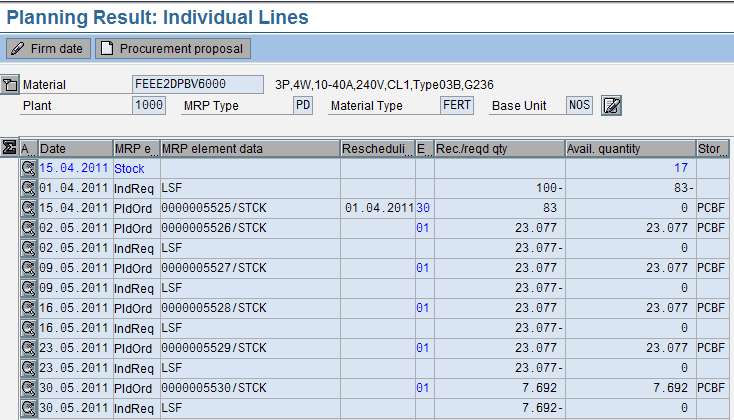

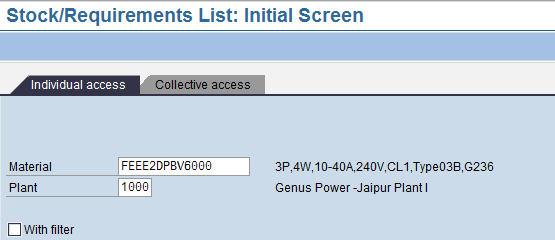

Now

we will convert planned order to production order for shop floor execution.

GOTO

MD04,

|

Field Name |

Description |

Values |

|

Material |

It should be Alphanumeric key uniquely

identifying the material. |

Example: FEEE20PBV6000 |

|

Plant |

Key uniquely identifying

a plant. |

Example:1000 |

Now

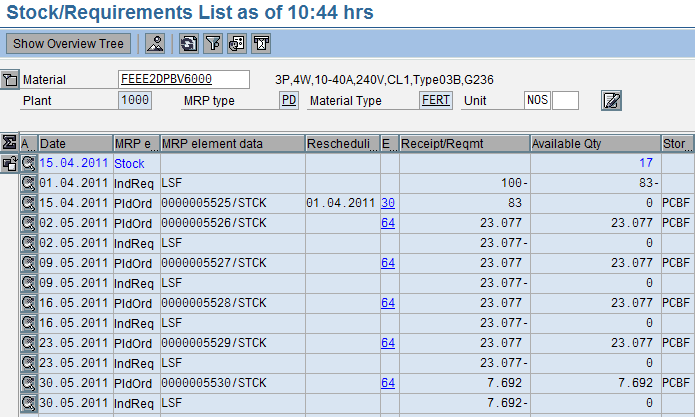

enter, you will reach the below screen:

Above

screen is showing MRP results.

Double

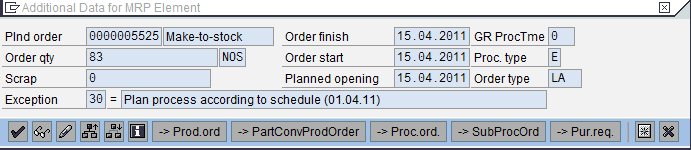

click on Planned order 0000005525/STCK, system will pop-up the below screen:

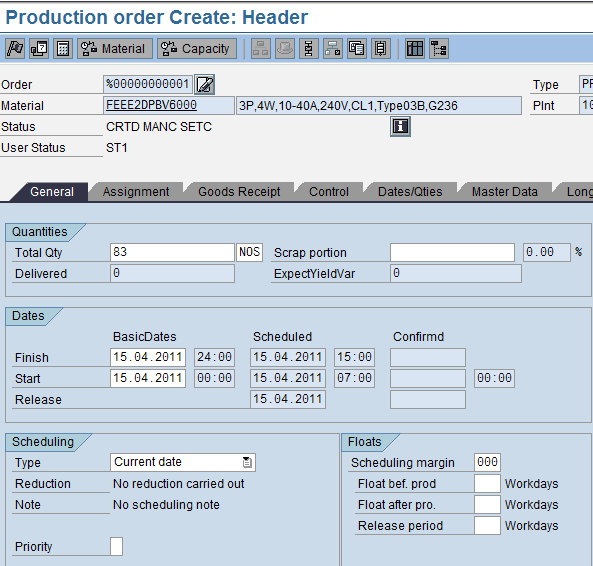

Click

on Prod.ord. TAB

Here we will do the Material

availability check/Release & all other production order activity as per

production order manual.